- Maximum Speed: 200 m/min – 800 bags/min

- Cutting/Cut-off Length: 110 – 420 mm

- Bag Length: 100 – 410 mm

- Bag Width: 55 – 350 mm

- Gusset Width (Open): 0 - 160 mm

- Automatic Bottom Glue Feeding

- Automatic Ink Pump System

- Automatic Side Glue System with Nozzle

- Dr.Chamber Blade and Ceramic Anilox

- Shaftless Unwinder

- Sleeve System

Contact Us For Sale

Emin Özdemir

Area Sales Manager - Türkiye & Middle East

Mehmet Susatan

Area Sales Manager - Europe & America

Mete Karatas

Sales Specialist

Tunç Bayram

European Business Development Executive

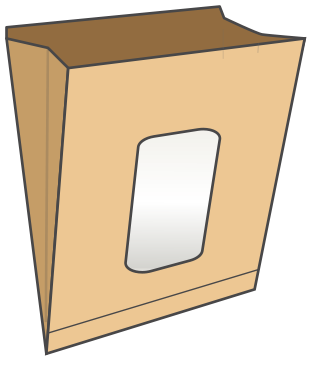

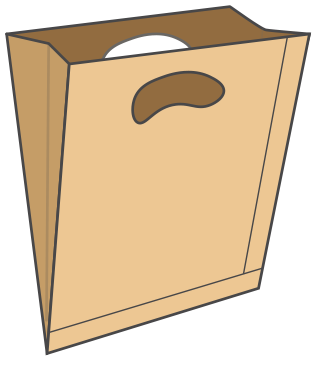

Die Cut Window Unit

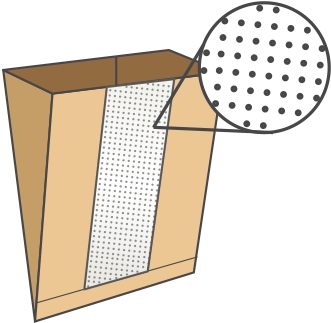

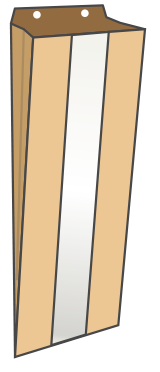

Die Cut Window Unit Microperforation Unit

Microperforation Unit Microperforation Unit

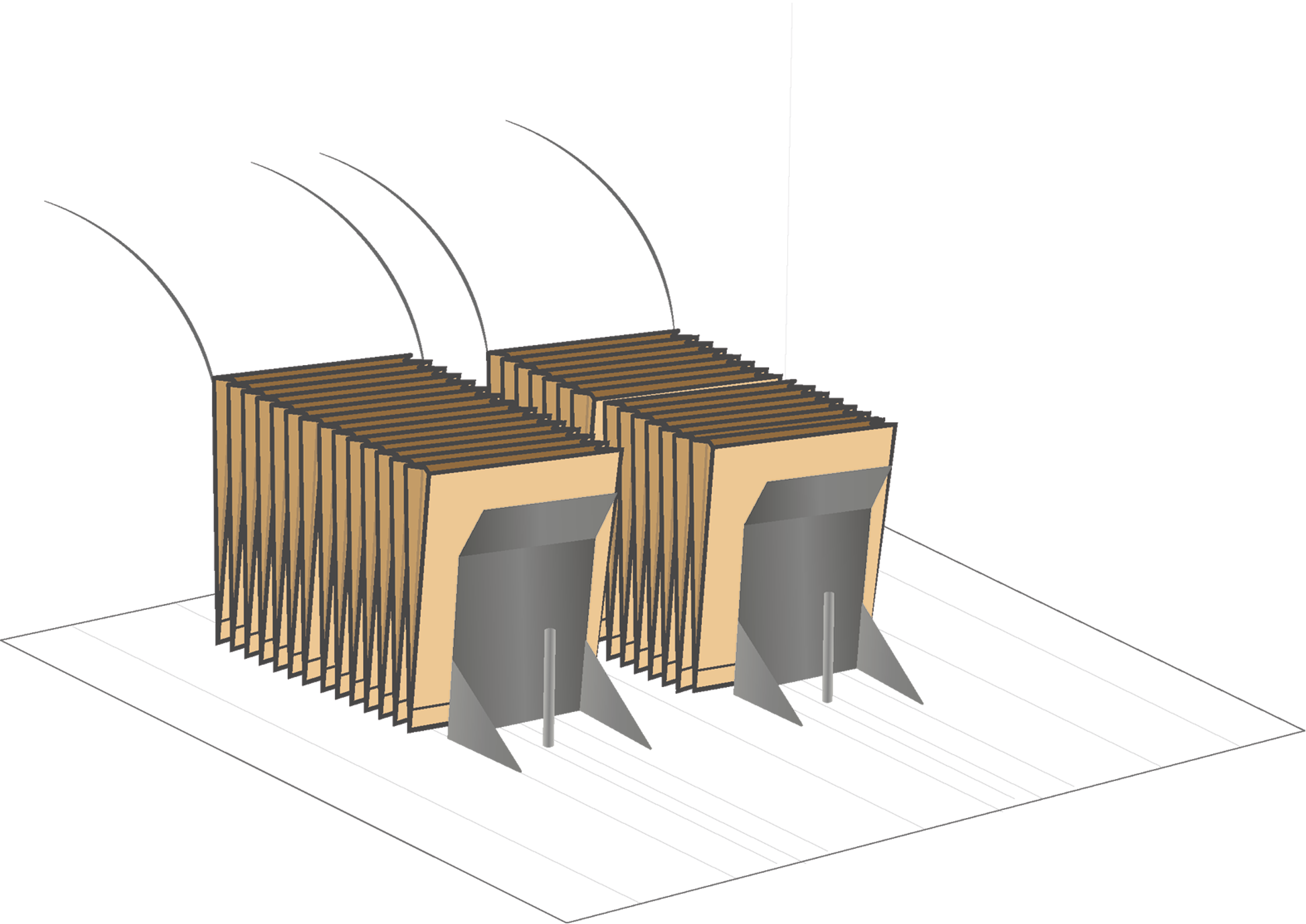

Microperforation Unit Wicket Unit

Wicket Unit Waxer / Prafin Unit

Waxer / Prafin Unit Twin Stream

Twin Stream