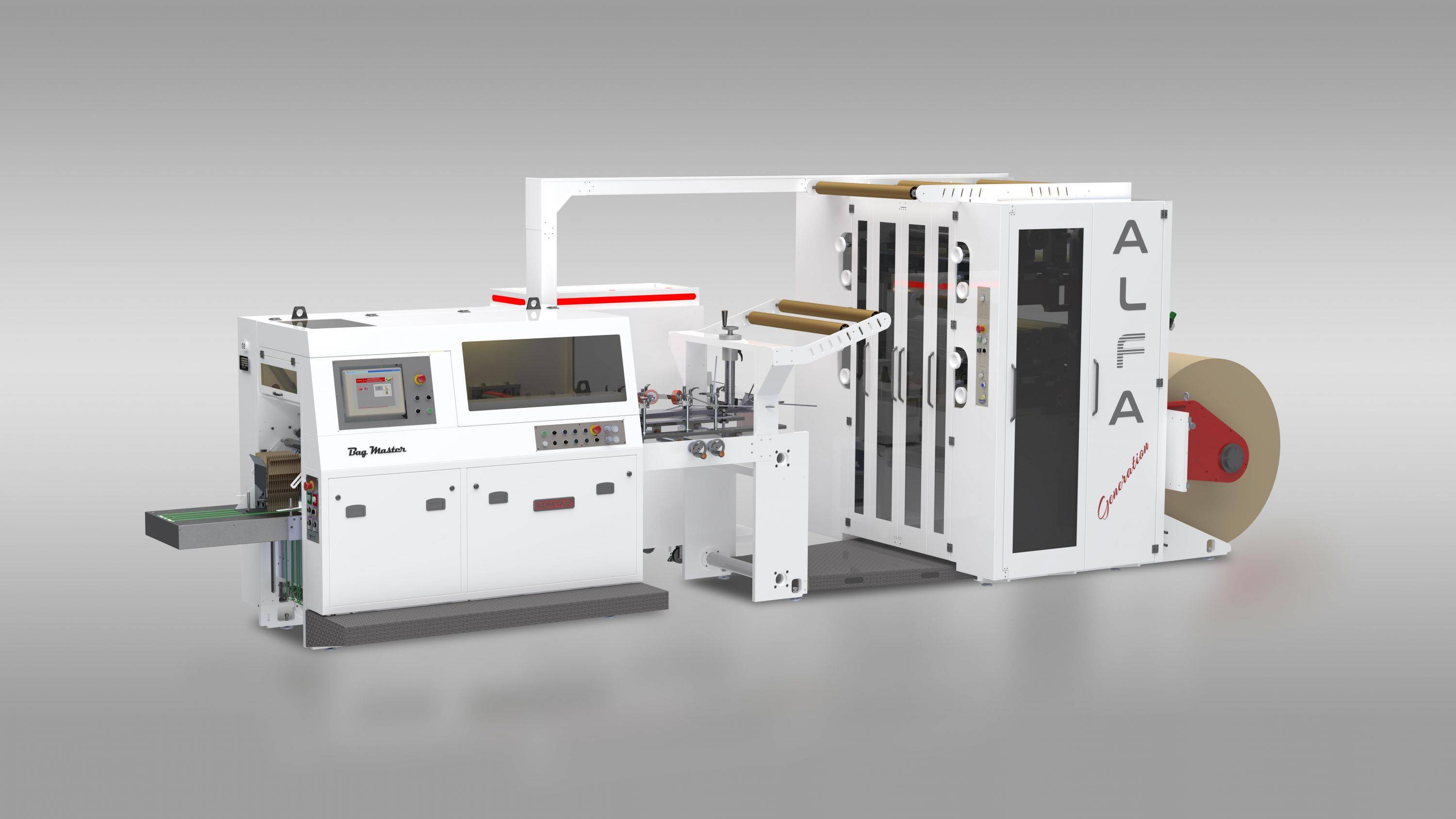

Capable of making 800 flat and satchel paper bags per minute, this machine is suitable for market requirements and ideal for efficient and competitive bag production. You can print two colors and produce paper bags with or without windows. You can produce baguette bread bags, sandwich bags, and pastry paper packaging products with this machine.

KEY FEATURES

Lesser Electric Consumption,

More Efficient Adhesive Consumption

Efficient Use of Space

Compact Structure

Glue Saving

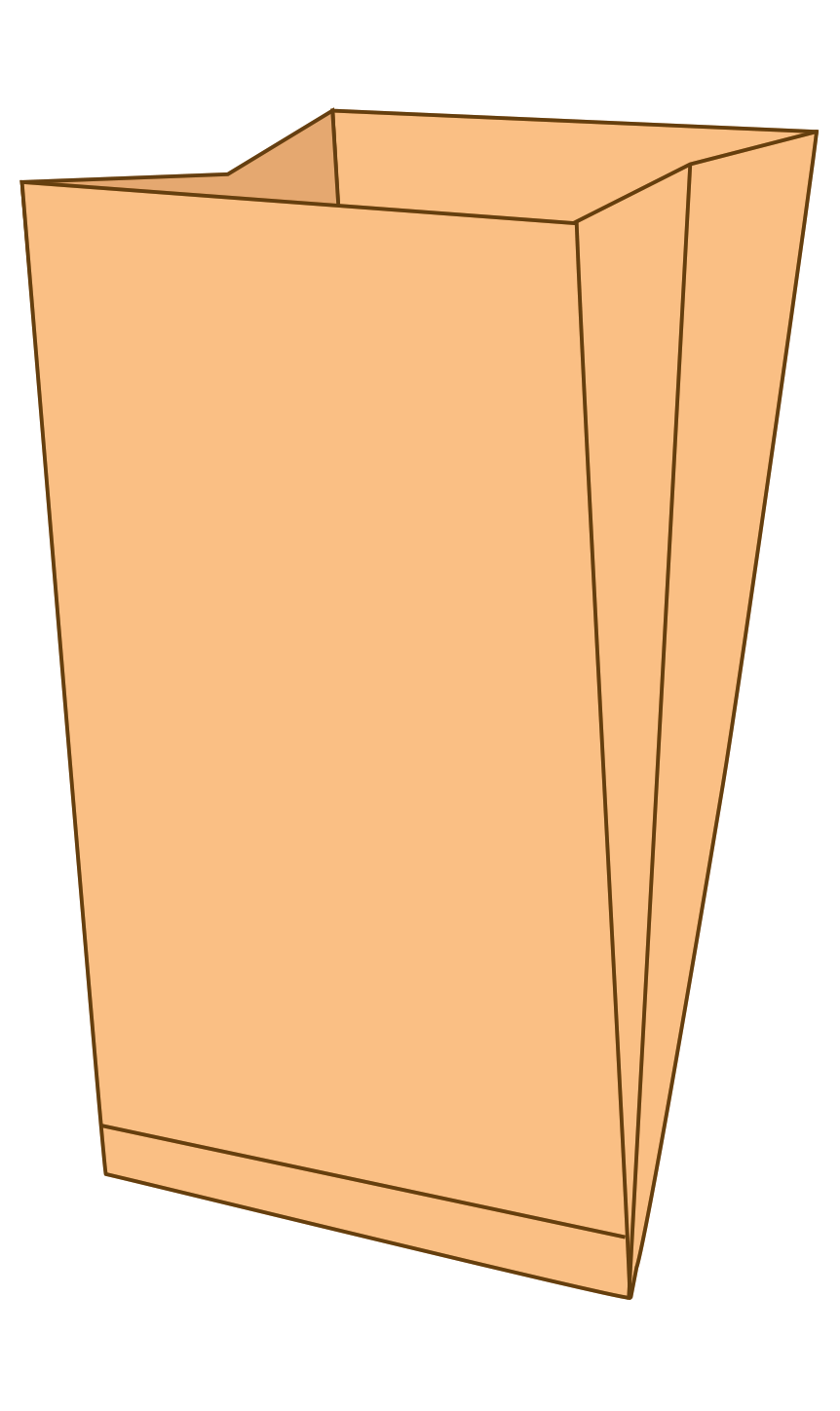

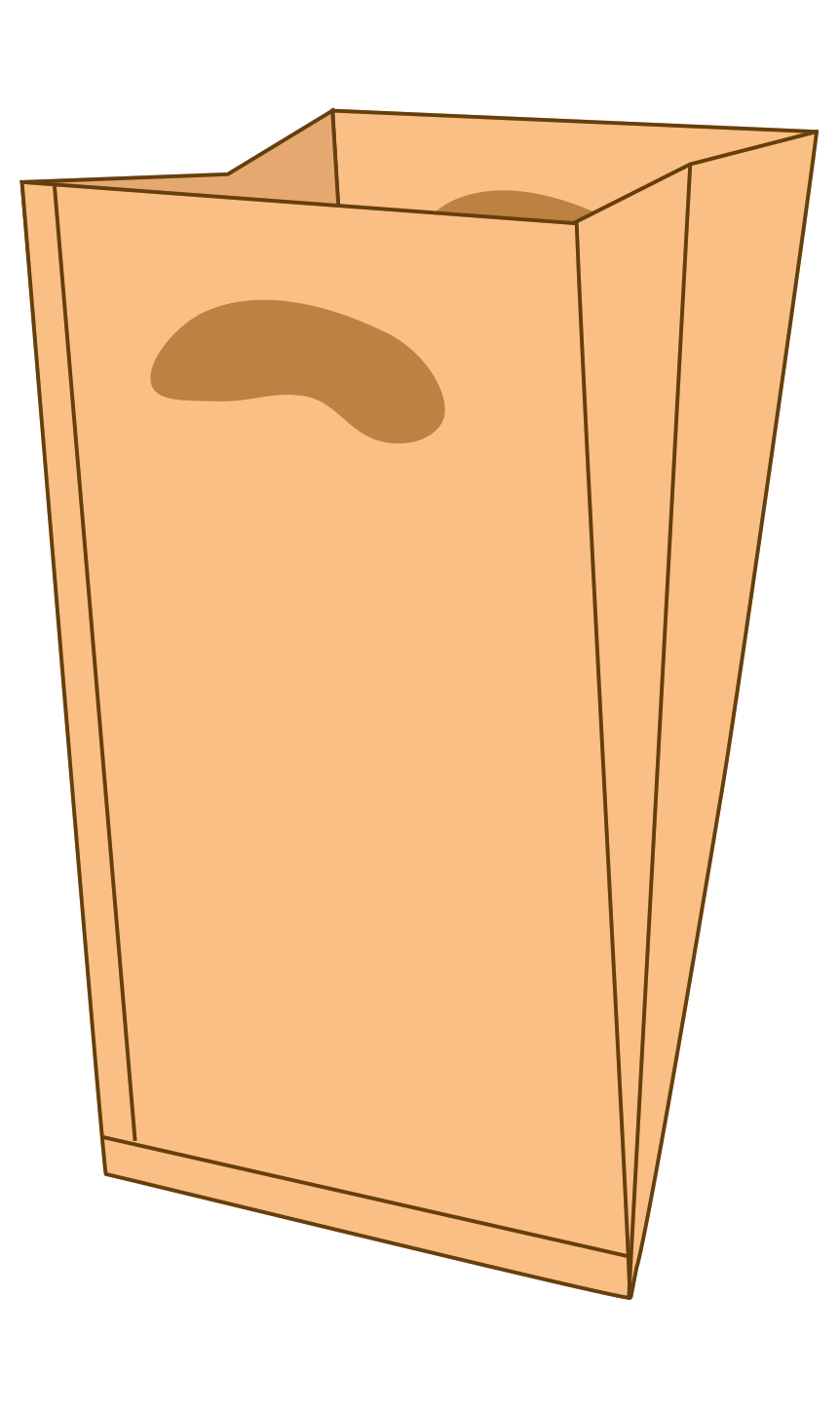

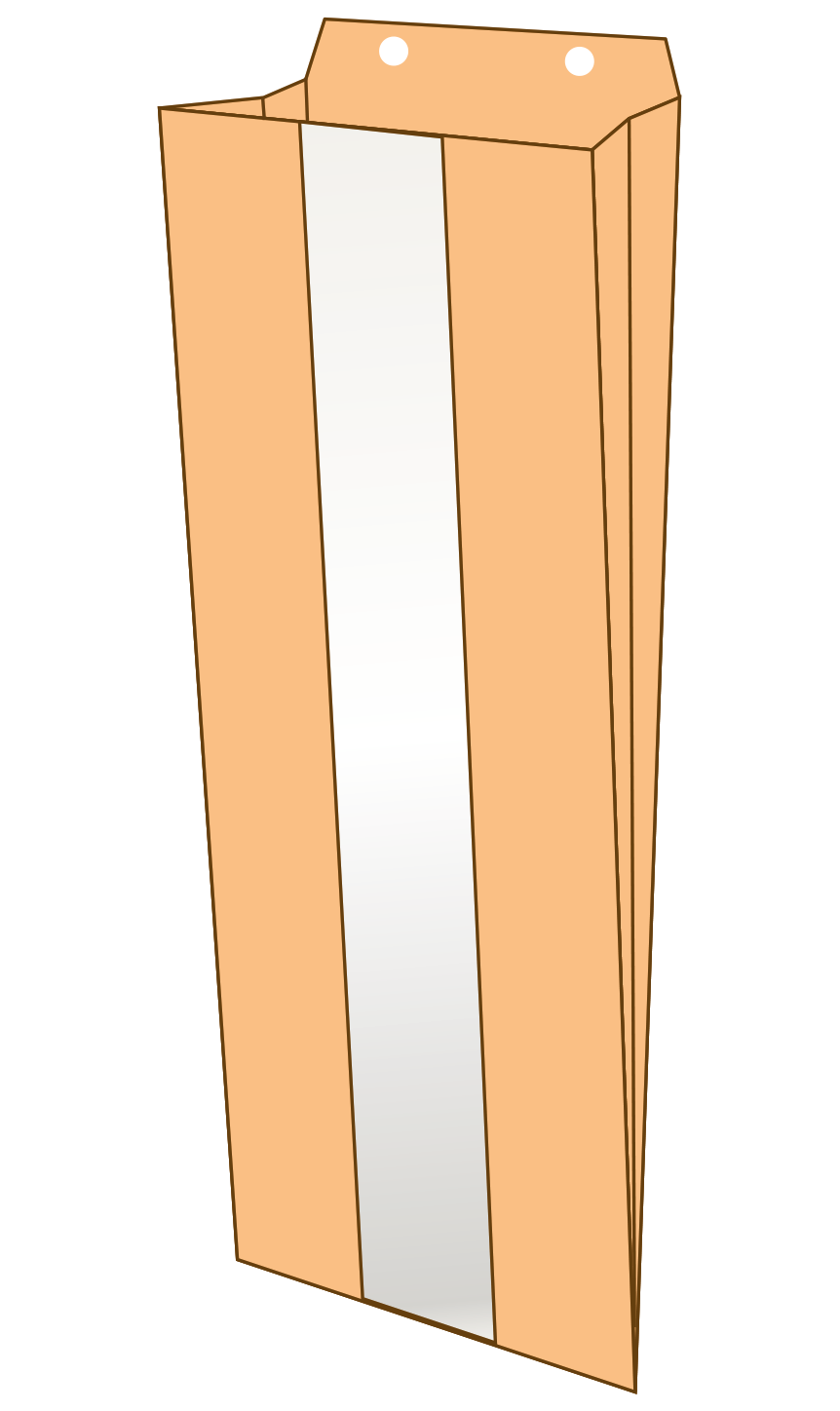

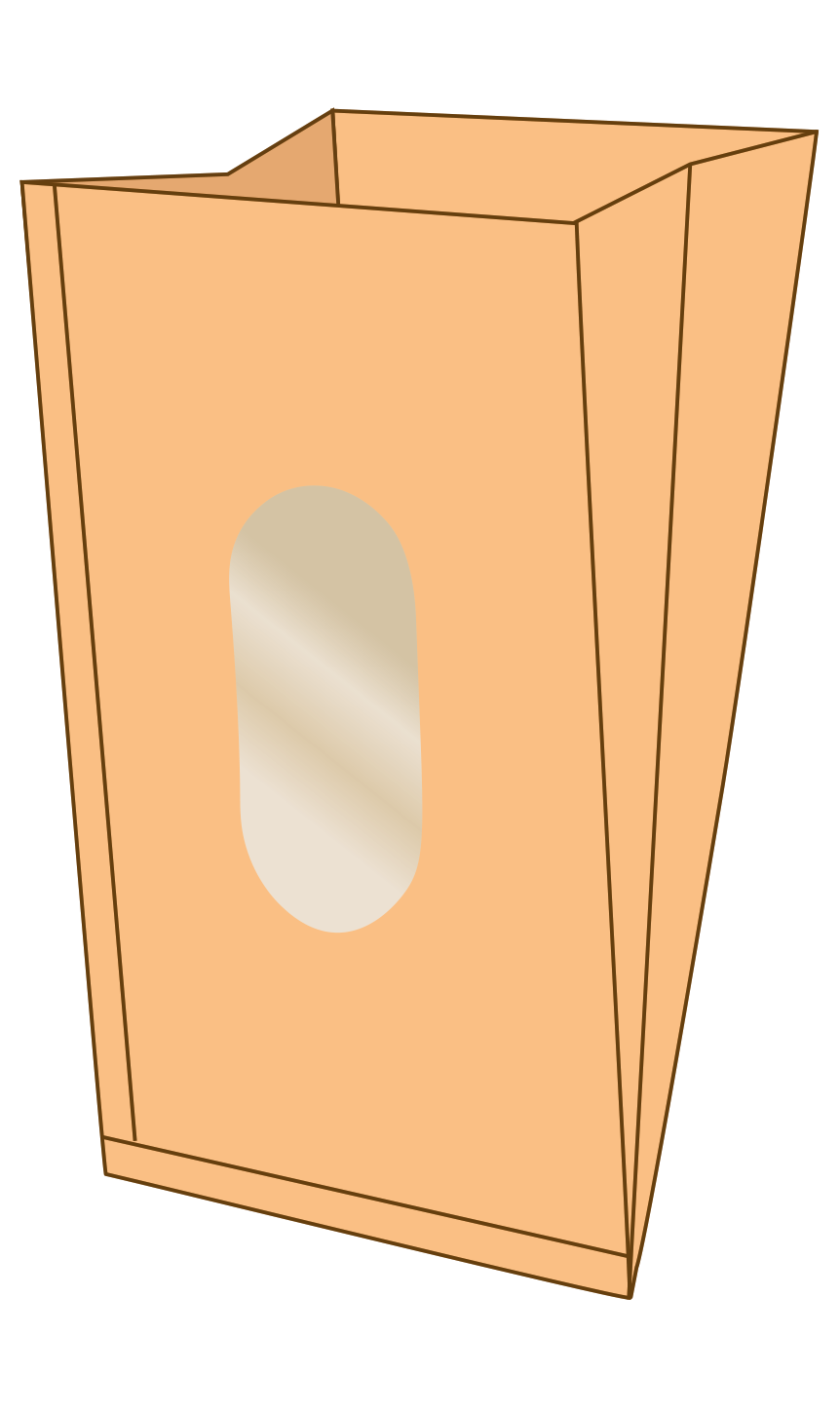

APPLICATION EXAMPLES

Designed for the Production of Bakery bags

Paper Bags with and Without Windows Are Frequently Used in the Fast Food Sector

Maximum Speed: 200 m/min – 800 bags/min

Cutting/Cut-off Length: 160 – 780 mm

Bag Length: 150 – 770 mm

Bag Width: 80 – 350 mm

Gusset Depth: Max. 80 mm

Cold Glue System

Hot Glue System

Winding Group /B.O.P.P Warp (For Windowed Bag Production)

4 or 6 Color In-line Flexo Printing Unit

Extra Color Unit (Flexo)

Wicket Unit No Print ( For automatic bread filling machines)

Wicket Unit For 4 or 6 Color ( For automatic bread filling machines)

Paraffin Unit (Waxer 900)

Twin Stream (Double Line)

L Bag Twin Stream

Lateral Control

BOPP + Unwinder Unit 900

Unwinder Unit 900

Rewinder Unit 600

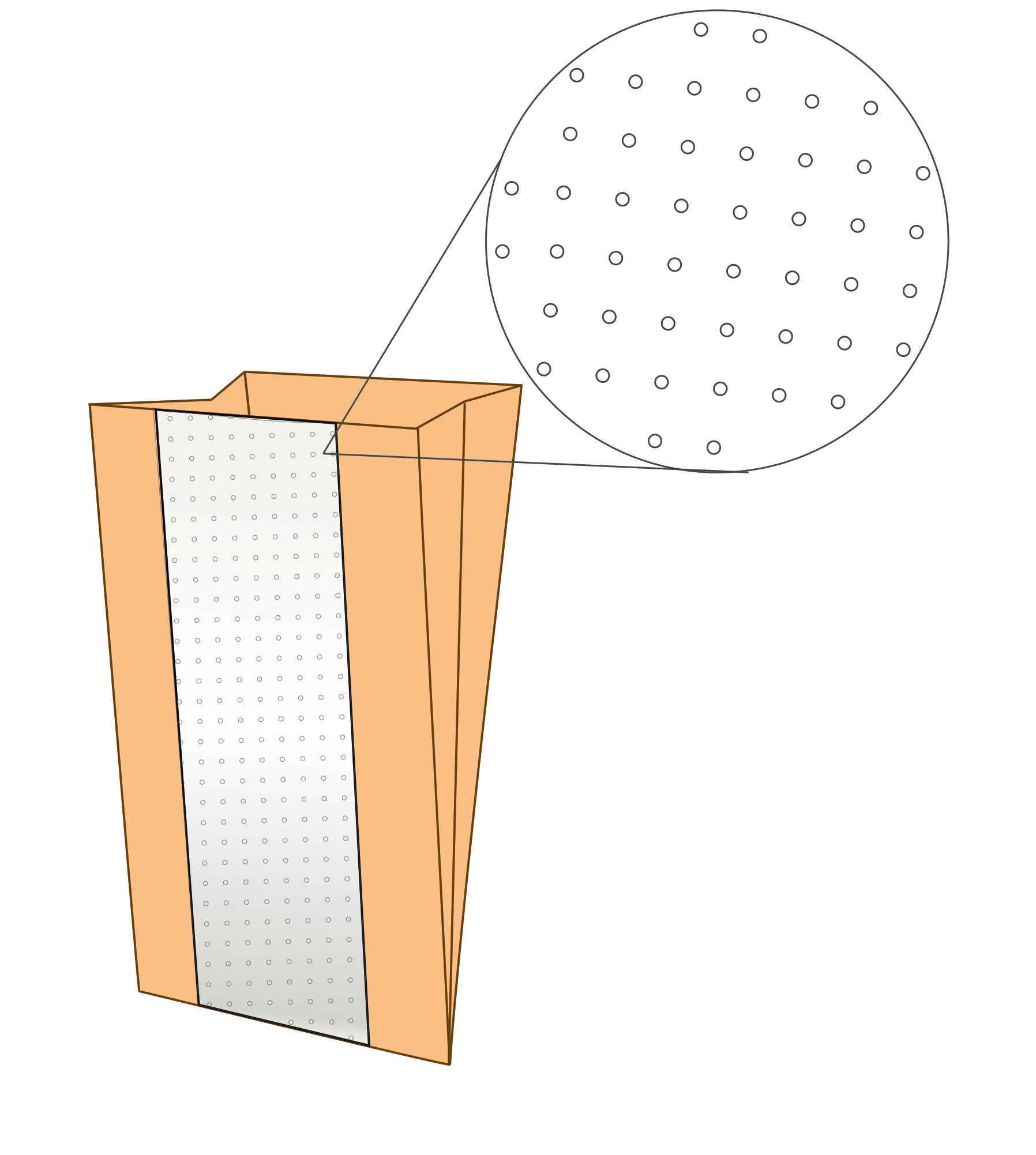

Microperforation Unit

Die Cut Window + Lamination

Punched Handle Unit

BST Web Guide System

360-Degree Motorized Longitudinal Register